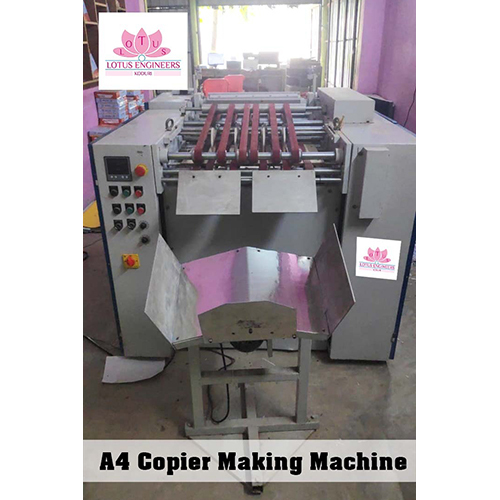

A4 Paper Printing Machine

3500000 INR/Unit

Product Details:

X

A4 Paper Printing Machine Price And Quantity

- 3500000 INR/Unit

- 1 Unit

A4 Paper Printing Machine Trade Information

- 4 Unit Per Month

- 20-30 Days

- All India

Product Description

This A4 Paper Printing Machine is one of the best models available in the market. It is used to produce sharp V-Type bottom paper bag with the application of jumbo paper rolls. The machine design supports coated paper, medico paper, ribbed kraft paper, kraft paper, grease-proof paper, and others. Its operation and application saved a lot of labor cost since it automates all the processes such as roll feeding, perforating, side gluing, tube forming, tube cutting off, bottom folding and gluing, and accumulating the finished bags. This A4 Paper Printing Machine is known to have benefits of simple operation, higher efficacy, and more stable operation. Using this machine, various types of paper bags that can be prepared are bread paper bags, food paper bags, snack paper bags, dry fruit paper bags and eco-friendly paper bags.

Features of A4 Paper Printing Machine

- HMI/PLC touch screen human-computer interface

- Simple operation and control

- In-built optical fiber

- Steady operating at high speed

- Servo control system

- Precise tracking of the printed bags

- Raw material loading interface is based on pneumatic cylinder up and down structure

- Automatic tension control for the unwinding

- Robust, durable and heavy duty structure

Product Specifications

| Gusset | 178 mm |

| Max Paper Roll Dia. | 1000 mm |

| Paper Core Dia. | 76 mm |

| Paper Roll Width | 10"(250 mm) |

| Paper Thickness | 30 GSM |

| Printing Type | Flexo |

| Printing Units | 2 Colors |

| Dimension | 6000 mm X 2500 mm X 2600 mm |

| Voltage | 440 V |

| Power | 5 KW |

| Max Bag Width | 3"(70 mm) |

| Max Bag Length | 6"(160 mm) |

| Automation Grade | Semi Automatic |

| Capacity | 600 pcs/min. |

| Bag Material | Paper |

| Machine Weight | 3500 kg |

| Usage/Application | Snack Paper Bag, Food Paper Bag & Other Eco-friendly Bags |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'A4 Size paper cutting machine' category

GST : 27AWTPK8597P1Z0

No 30 /27, No 5/558, Viibhav Raj Complex, Near Laxmi Industrial, Dhayari,Pune - 411041, Maharashtra, India

Phone :07971189766

|

|

LOTUS ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |